MIT Successfully Manages to Make 3D Printed Glass

A new development at MIT has shown us how to expand the 3D printing technology and use it to make 3D printed glass.

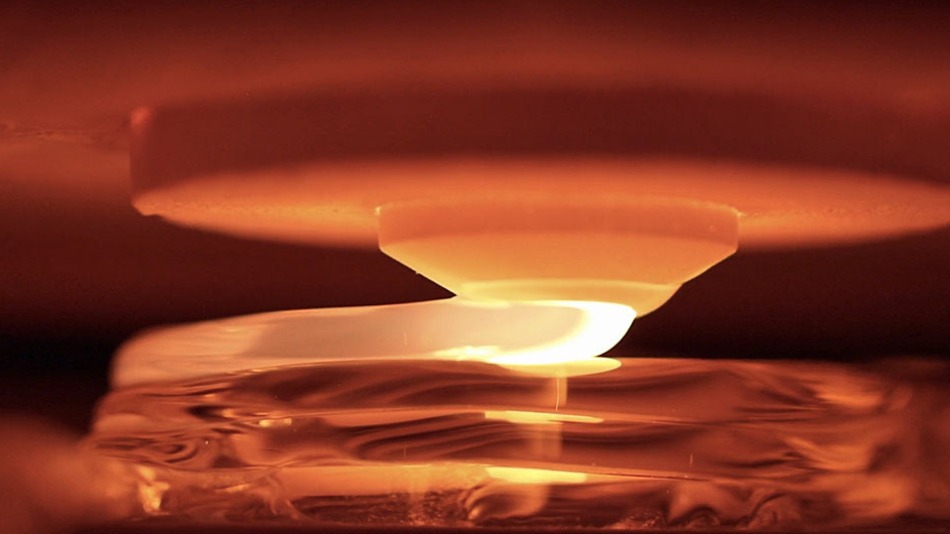

A method called G3DP is said to allow the creation of complex 3D glass structures to be printed in a similar fashion to plastic constructs. This process uses two chambers – one that acts as a kiln cartridge and the other that works to melt structures together. The molten glass is then distributed through an alumina-zircon-silica nozzle that pours the material out smoothly.

The entire process was developed by a team including the MIT Media Lab’s Mediated Matter group, the MIT Glass Lab, the Wyss Institute and MIT’s Mechanical Engineering Department. This new breakthrough is also said to advance the process of creating fiber optic cables that transmit data more efficiently. One of the project’s leaders, Neri Oxman, while conducting research said :

“Now [we can] consider printable optoelectronics, or the possibility of combining optical fibers for high-speed data transmission by light, combined within glass printed building facades.”

One of the research’s vision is to one day employ this technology in building facades. However, reports suggest that the entire process is slow and therefore not efficient enough, but it can still create complex structures for other purposes.

There has been no information regarding the implementation of this device by any commercial application, but the MIT G3DP is going to be showcased at an exhibit in the Cooper Hewitt, Smithsonian Design Museum in New York next year.

! For i

! For i